DeBulCo and innovative robotic welding – MIG/TIG with automatic torch change

For us, automation and optimization of work processes are two extremely important activities and that is why we have reintroduced something new – robotic MIG/TIG welding with automatic torch change. Today we will tell you more about it!

Welding – what is it?

Welding is a process by which a monolithic joint is formed from welded parts. In other words, by welding we join two separate parts into a single whole. Molecular bonds are formed between them, ensuring continuity of structure in the welded area, or in simpler terms – these two parts can hardly be separated from each other anymore.

Welding methods

There are different methods to optimize the welding process, based on different materials and applications, including:

- Arc welding – an electric current is used to melt the metal. The most popular such methods are MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas).

- Friction welding – welding, based on friction between two materials – the method can be used for non-metals.

- Electron beam welding – an electron beam is used to melt metals. The method is carried out in a vacuum and is usually used for thicker components.

- Plasma welding – plasma is used as a heat source.

- Laser welding – a high-speed method that uses a laser beam for welding. It is very precise and can also be used for non-metals.

- Resistance Welding – uses the heat generated by the current between electrodes to weld common steel components.

MIG welding – what is it?

MIG (Metal Inert Gas) is a welding method that uses an active gas. In this method, a metal electrode is used with a consumable and a shielding gas, an electric arc is ignited between a fusing electrode, most often in the form of a coiled wire.

This method has a number of advantages, the main ones being high productivity and high quality of the welding seams. Additionally, MIG welding is much cheaper than TIG welding and training a qualified welder is quicker and hassle-free. In addition, this process is subject to robotization, as the accuracy requirements of the welded parts and welding fixtures are not as high as with TIG.

TIG welding – what is it?

TIG (Tungsten Inert Gas) is a method of electric arc welding in a protected environment. This method uses a non-melting electrode and a shielded medium of argon with another gas added, such as helium.

This method also has its advantages, the main one being high quality welds with a very precise weld seam free of spatter and slag. This saves additional operations to improve the finish. The main disadvantage of the method is that, when performed manually, it requires a highly skilled and qualified welder. It is also much slower than the alternative MIG. TIG can also be robotic but in this case, especially when working without filler material, accuracy can be a challenge.

Welding robotic cell OTC DAIHEN (Japan)

DeBulCo’s commitment to applying the best and most innovative technologies, as well as the vision to offer the highest quality product, led to the decision to invest in an additional robotic cell.

The company chosen for this is OTC Daihen, which offers a complete solution including a complete welding cell. The robot has a 2 meter reach and a load capacity of up to 500 kilograms. The cell is supplied with two current sources – one for MIG and one for TIG welding with the ability to weld with and without filler material. All components are from a single manufacturer, which shortens the implementation enormously, as well as preventing risks of not good integration and subsequent incompatibilities. The components are integrated and the processes are synchronized to perfection before delivery, even under factory conditions.

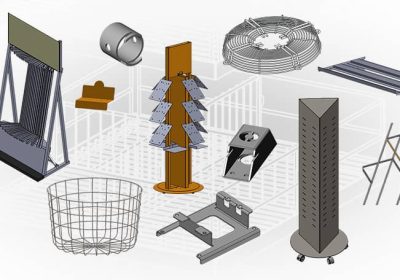

With the help of robotic welding DeBulCo provides its customers with fast and quality production of their metal constructions in medium and large series – metal parts made of sheet metal, pipes and wire, product bodies, metal furniture, shop furniture, advertising displays and everything that needs precise welding.

If you need more information about our services, send us an inquiry at info@debulco.bg or call us under +359888703887.