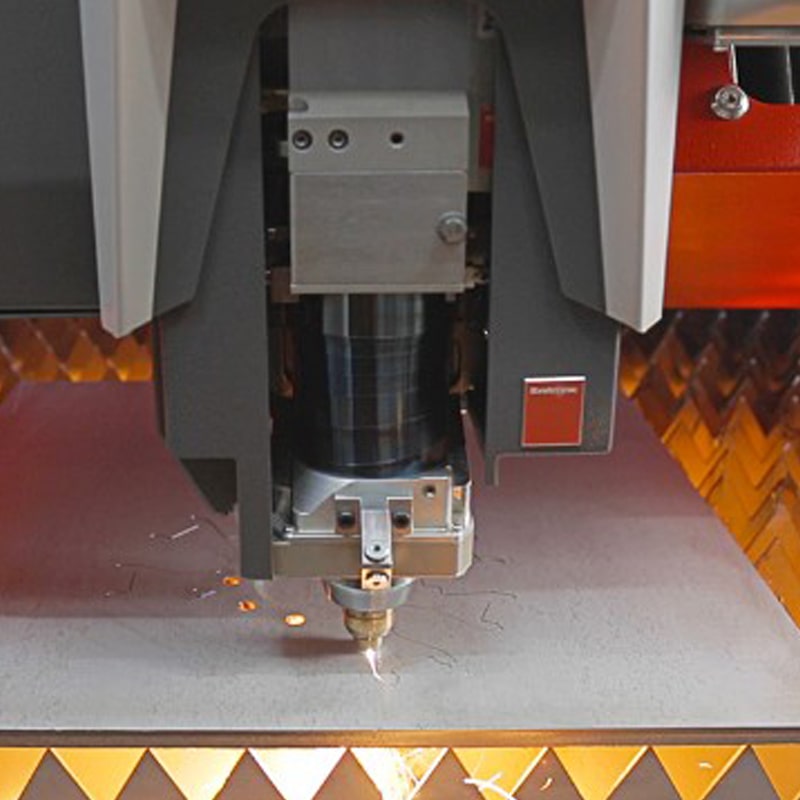

New Laser machine with automatization by DeBulCo

We are happy to announce the successful installation of a new laser cutting machine at DeBulCo. The machine is a powerful 10KW ByStar fiber laser machine with automatization ByTrans Extended. The System comes from the reputable Swiss producer Bystronic and comes to replace after years of good work the old one CO2 ByStar 4,4kW at DeBulCo’s production. The machine can cut steel sheets with dimensioned 1500 x 3000 mm and thickness till 25 mm at enormous speed thank to its electromagnetic drive system, laser power and state of the art laser technology. In addition, loading of the sheet, unloading of the skeleton and even the parts, when they are enough big can be fully automatic with the help of the attached ByTrans Extended.

What are the benefits of this replacement?

In short – the new fiber laser cutting technology increases tremendously the cutting speed at drastically lower operational costs.

At one side that is due to the different technology – fiber laser has much more power density and absorption because of the nature of the beam and the wavelength. The other is the increased power – 10kW vs. 4,4kW and finally the drives are electromagnetic with remarkable acceleration. That allows much higher feed rates hence more parts per hour and additional machine capacity. In our case we notice 3-5 times increased productivity compared to the old 4,4 CO2 laser.

At the other hand are the reduced costs. The electricity consumption is about two times lower, considering the laser power is 2,27 times higher. Combined with our solar plant we can now offer to our customers along with efficiency, ecological “green” laser parts. Additional important advantages are – reduced start time of the machine, no need of beam optics maintenance, automatic nozzle change. On daily basis that all leads to productivity and increased capacity.

What is though fast machine without fast handling? There is indeed no big sense if the machine cuts fast the parts and then waits to be unloaded and loaded with new sheet. So, we equipped our laser machine with automatization ByTrans Extended. The unit ca work with two different material types, prepares the sheet and loads the machine fully automatically. The skeleton can be removed also automatically. In addition, if the parts are bigger, they can be removed and sorted also in an automatic way. The whole process is synchronized to the machine. This minimized the non-operating time and allows the machine to cut continuously and under some conditions without need of operator’s supervision.

As a result of this investment there is increase of laser cutting capacity. Our customers can rely on faster delivery times and attractive prices. The laser cutting process is now much more ecological, fast, and efficient.