DeBulCo and innovative robotic welding – MIG/TIG with automatic torch change

For us, automation and optimization of work processes are two extremely important activities and that is why we have…

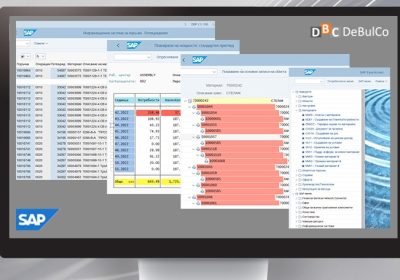

The SAP ERP system and its benefits for our customers

Back in 2019, we successfully integrated the high-tech solution S/4 HANA, provided by SAP, into our management system. This…

DeBulCo Introduces Laser-Punch with Automation

An innovative technology designed to benefit customers We are pleased to share that DeBulCo has installed and launched a…

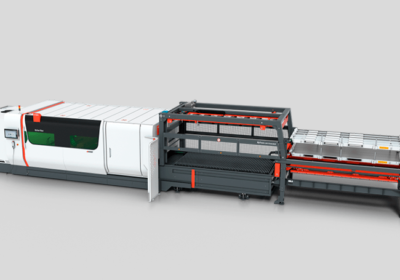

Laser with automation BYSTRONIC

DeBulCo installed and put into operation a powerful automated laser cutting system ByStar Fiber 3015 10 kW. The system is…

New robotic welding cell MIG TIG

DeBulCo installed and put into operation an 8-axis robotic welding cell of the Japanese company DAIHEN. Complex parts are…

New fully automated laser punch system PRIMA POWER

DeBulCo has installed and put into operation a fully automated laser punch system of PRIMA POWER. The system is…

New electrical logistics equipment

Another small step towards our carbon neutrality. New logistics equipment powered by electricity. The batteries will be charged by…

New robotic system for grinding PEITZMEIER

DeBulCo has installed and put into operation a robotic system for grinding. Large-sized parts (up to 3000 mm and 170 kg)…

New photovoltaic power plant

DeBulCo built and put into operation a photovoltaic power plant for its own needs with a capacity of 170.2…