Production process of DeBulCo Ltd

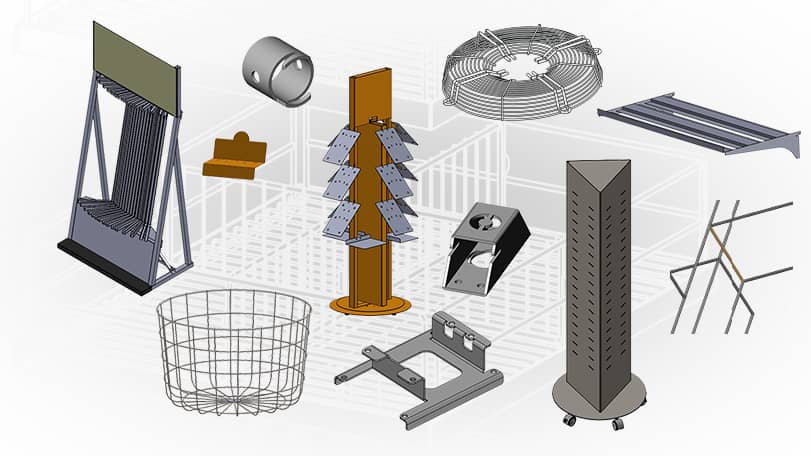

DeBulCo manufactures metal products for the industry, premium advertising racks and shop furniture. Our production base is equipped with modern machines of leading manufacturers. Thanks to our technical capabilities, we can manufacture various metal products, both in single pieces and in serial production, incl. non-standard products as requested by the customer. Our production cycle has been developed since many years of experience and guarantees the professional execution of each order from the idea of the project to the delivery of the finished product to the customer.

The entire production process of DeBulCo includes:

- Planning and design

- Market research: Each customer has specific needs and requirements, therefore DeBulCo strives to understand where, how and for what purposes the respective product will be used, in order to provide the best solution tailored to the customer’s wishes.

- Product development: Design and prototyping of new products. Our team of specialists produces the first pilot unit of the new product and provides it to the customer for approval, making corrections if necessary.

- Production Planning: After the approval of the prototype, the serial production of the product is planned, determining the necessary resources, materials and technologies.

- Supply of materials

- Purchase of raw materials: Once we know what is needed to manufacture the product, we proceed to select suppliers to ensure high quality materials.

- Quality control: The necessary materials are checked and tested for compliance with all standards and a certain quality.

- Production

- Preparation of production lines: Production starts with setting the working parameters of the machines.

- Component manufacturing: Production of individual components from raw materials.

- Product assembly: Assembling the components into finished products.

- Automation of processes: Implementing automated systems in manufacturing processes is key to increasing efficiency and reducing human error.

- Quality control

- Tests and inspections: Conducting various tests to ensure product quality. DeBulCo has a control laboratory in the production base, which is equipped with modern measuring equipment to improve quality control when measuring 3D details.

- Certification: Our company is certified according to the ISO 9001:2015 quality management system which proves that the company’s products are at a high level and are competitive on the global market.

- Packaging and storage

- Packaging of finished products: Ensuring safe and secure packaging.

- Storage: Organization and management of warehouse stocks.

- Delivery

- Logistics: Planning and implementation of deliveries to customers. We always strive to ensure compliance with production deadlines and timely delivery of finished products to customers. Thanks to the integrated SAP ERP system, all orders are processed on time.

- Customer relations: Keeping in touch with customers and feedback.

- Continuous improvement

- Manufacturing Process Analysis: DeBulCo constantly analyzes and evaluates the efficiency of the production of metal products and finds ways to automate and optimize production processes.

- Investments in new technologies: Today, the biggest challenge for most companies is to constantly reduce production costs by implementation of modern technologies and innovations that contribute to more efficient use of resources, the reduction of material losses and the optimization of operating costs.

Satisfied customers are a top priority for DeBulCo. Therefore, the production process of our company is well structured and optimized, focused on quality and efficiency, while striving to meet the needs of our customers and remain competitive on the market.

If you want to learn more about the services of DeBulCo, contact us by sending an email to info@debulco.bg or call 0888 703887.