Swiss precision with DeBulCo’s new lathe

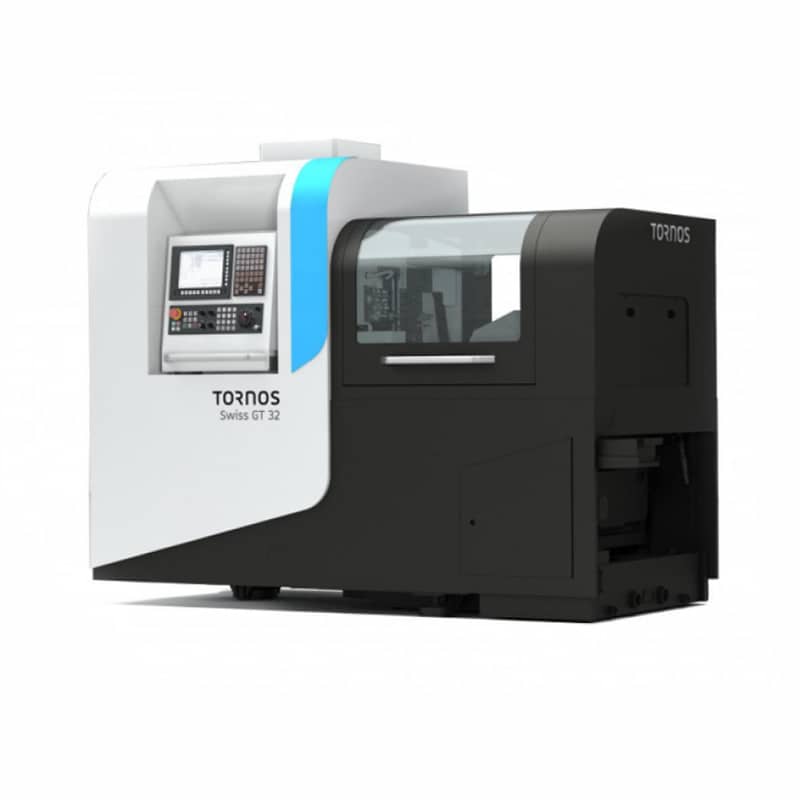

We are happy to announce the successful installation and commissioning of our new TORNOS GT32B Swiss Type lathe by the renowned Swiss machine builder TORNOS.

Why did we trust TORNOS?

Our customers deserve the best. This type of lathe is called Swiss type for a reason. It was invented where TORNOS is – in Moutier, Switzerland. After a thorough analysis, we found that more than 125 years of tradition gives its results even today – excellent quality and functionality, precision down to the smallest detail.

Main characteristics of our TORNOS GT32B

- Turning and milling of bars from Ø5 to Ø32 mm.

- Two-spindle simultaneous processing

- Standard length of the processed part is up to 200 mm.

- Bar feeder for processing materials up to 3 m.

- Possibility to work with and without a guide bushing.

- Spindle speed up to 8000 rpm.

- Speed of active instruments (up to 16 pcs) up to 6000 rpm.

- Integrated fire extinguishing system that allows safe handling of flammable materials such as aluminum and titanium.

- Automatic conveyor for the output of manufactured parts, which ensures continuous autonomous operation.

- Specialized programming software that simplifies setup and shortens the time to get a part into production.

Advantages of the machine

The machine is a natural extension of DeBulCo’s newly organized metalworking department. In addition to the company’s “conventional” lathes, Swiss-type ones have some significant advantages.

- The presence of a bushing that “guides” the processed material. The technological solution was invented namely in Switzerland at the end of the 19th and the beginning of the 20th century to meet the need for high-precision details for Swiss watchmakers. High accuracy and the possibility of manufacturing relatively long and complex parts with small diameters due to the elimination of vibrations is achieved. Thus, it becomes possible to manufacture parts that are impossible to produce with a conventional lathe or for which serious compromises with accuracy and productivity must be accepted.

- A specific arrangement of tools which are located on tool plates. This enables extremely fast change of tools during the work cycle.

- A serious advantage is also the presence of a powerful second spindle, on which finishing operations can be carried out simultaneously with the work of the main spindle. This results in a drastic reduction – up to two times – in processing time.

- The finished part is taken out of the machine via a conveyor, which implies autonomy.

What are the benefits

All these advantages allow for high-speed, efficient and high-quality production of difficult details with complex processing.

With the new investment, our customers receive high quality of their precise and complex turning and milling parts.

Due to the high productivity, a shortened delivery time and competitive prices are guaranteed.

Thanks to the modularity and wide capabilities of the machine, as well as the built-in B-axis, even the most complex precision details are processed for our customers, including ones coming from demanding industries such as electronics, automotive and medical technology.

If you want to learn more about DeBulCo’s services, contact us at info@debulco.bg or by calling 0888 703887.